3451 Operating Lumber and 3469 Ore Dump Car

Trash or Treasure? Cars Shown in Restored Operating Condition.

These cars were advertised used and operational at a very good price. Upon arrival, inspection revealed bug infestation, deep rust, corrosion in wiring, loose wires, broken wire, and wire shorting to car body. The coil cover was missing on the Ore Dump Car. The wheels did roll. I seriously considered throwing them in the trash. If I count the time and money involved in this restoration they were definitely not worth the trouble.

Restoration Began with Disassembly and Cleaning

Print Exploded Parts Diagrams for

Log Dump

and Coal Dump

Page 2 Parts Identification During Disassembly.

Use Part Numbers for Replacement Parts Order List.

PARTS ORDERED for BOTH CARS

for 3451 log dump

2 TC-110R coupler head & coil assy repro 7.50

2 TC-120 shoe contact spring reproduction

TC-22 knuckle spring (from my stock)

TC-23 knuckle pin black (from my stock)

3451-31 Contact Strip Reproduction (WSR-43)

for 3469 coal dump TT-208X slide shoe, plate & rivet kit 1.00 (2

each for coal and lumber)

2 6TC-12 Collector Shoe Spring

2 61-14 Brass Eyelet

25 for my stock 480-16 Knuckle Spring

for Coal Dump Car 3459-27

frame cover reproduction 3.00

misc. parts

480-18B black horseshoe washer

from my stock

Replacement wire - Wire-Plex 22-gauge (super flexible

wire)

Dirt and bugs were removed and parts are ready for a lamp oil (purified kerosene with odor removed) soak. Soaking loosens the harden grease and oil. After soaking parts were scrubbed clean with a toothbrush. After air drying parts were wiped and inspected for any repairs needed.

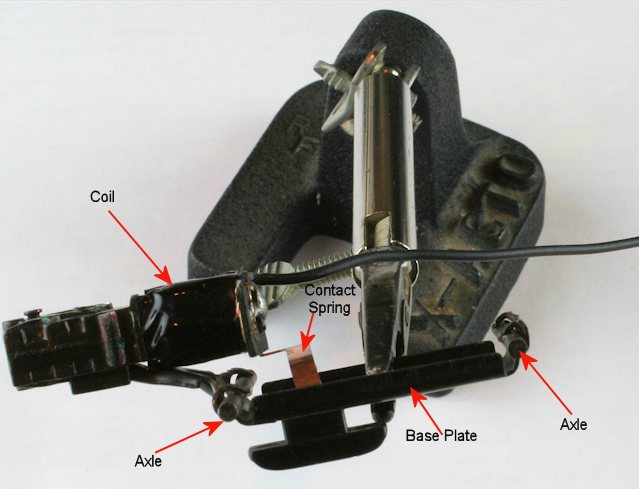

One of the log car axles was straightened. Rust and corrosion was removed with fine files and a wire brush in a Moto Tool. Electrical contact surfaces require the most attention.

The coil wires on the log car couplers had corroded and broken.

Replacing the coil couplers on the log car did not go well. I did it before and forgot how. I ruined two out of three replacement coils when over pressing the formed rivet when attaching to the truck with my Rivet/Wheel Press and Riveter. The only item not restored to excellent operating condition was one of the coils I squashed too hard.

Coil Coupler Replacement Sequence

Secure old coil to remove the coil at the rivet. Do

Not enlarge the mounting

hole in the base plate.

Start with #41 bit to remove the coil.

This is the old chuck used to hand ream the top ridge off the rivet.

Use a 11/64" bit or smaller.

Very gently remove most of the rivet ridge.

Gently pry the base plate off with a small screwdriver.

These are the closest tools I had to attach the coil coupler to the base plate. These tools are used with my Rivet/Wheel Press and Riveter . I managed to attach one replacement coupler correctly. I ruined two more by squshing too hard. I needed a better shaped cup for the base or a more patient finesse.

The contact replacement contact spring may not be an exact duplicate. For ease of soldering wire to contact spring, drill 1/16" hole in wiring tab (use punch then variable speed drilling).

Log Car Parts Ready for Wiring and Assembly

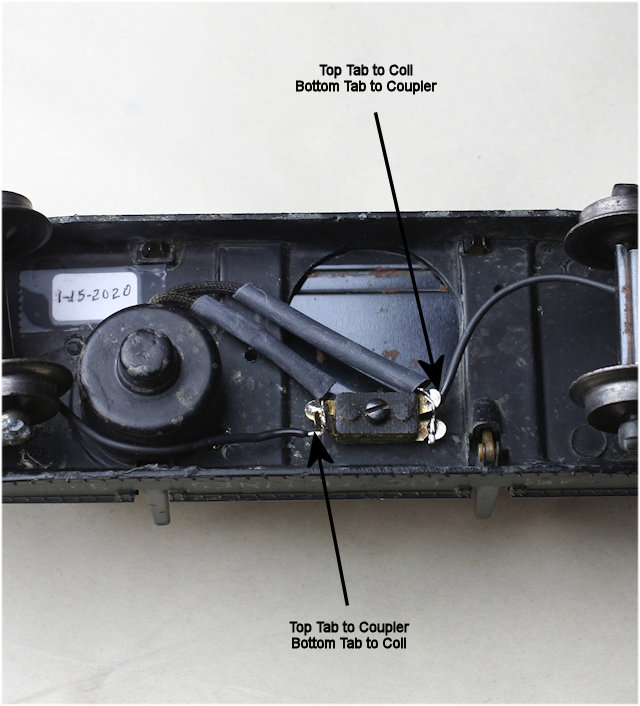

See Helpful Wring Information at

UCS-40 and RCS-20 Operating Track Section Controllers.

A log dump coil wire was shorting to the coil shield. The bare wire near the coil was coated with Liquid Tape and the cloth shield was repositioned.

REPLACE SLIDE SHOES ON BOTH CARS

Remove old shoe rivets using a 3/32" drill bit. Install new

rivets and shoes with the

Brakeman's Riveter.

Solder super flexible wires to rivet. See bottom of page 8

about

miscellaneous trucks.

Reassemble and Wire Coal Dump Car

Reference Documents

- Log Dump Car Service Manual

- Coal Dump Car Service Manual

- Lionel Truck Service Manual

- Operating Cars Wiring

- Dump Car Instructions

- UCS-40 and RCS-20 Operating Track Section Controllers

Return to Operating Cars and Accessories