UCS-40 and RCS-20 Operating Track Section Controllers

All Lionel Earlier Operating Track Sections are Controlled with the Same Controller.

Postwar UCS Controller Repair

The most common repairs for postwar controllers are cleaning the contacts and adjusting the springs.

Mark Wires Before Removal

Use tape or 3M Wire Markers in rolls or books.

After marking wires, remove from track and power bus bar.

| Log Controller

was inspected and serviced in place. |

Coal Dump

Controller Needed Bench Repair |

| Place the

Controller over a parts tray or clear surface before

removing base. Note broken and loose parts. The

# RCS-27 Spacer Button is a must have. Remove binding head screw from springs to clean electrical contacts with 240 grit wet or dry paper. See below for Controller operation. |

|

Refer to Diagram for Reassembly

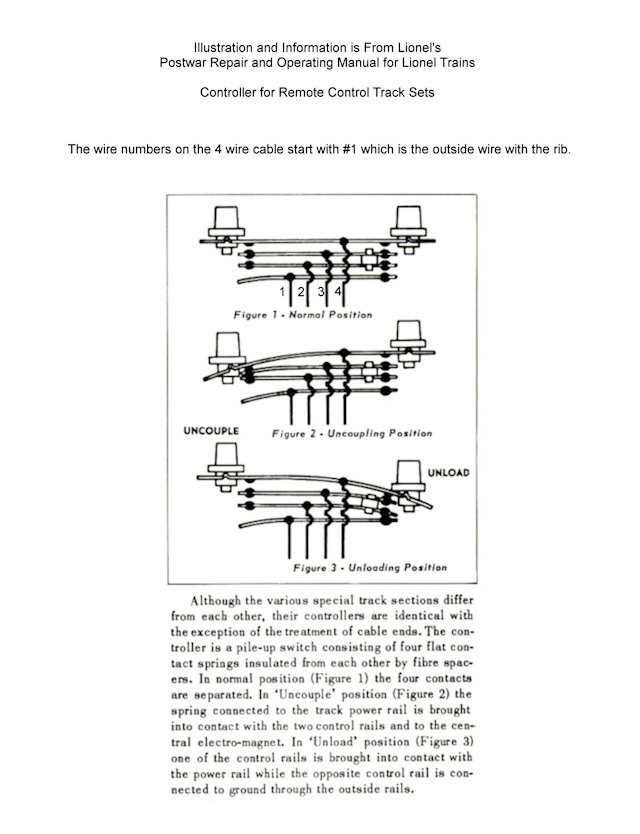

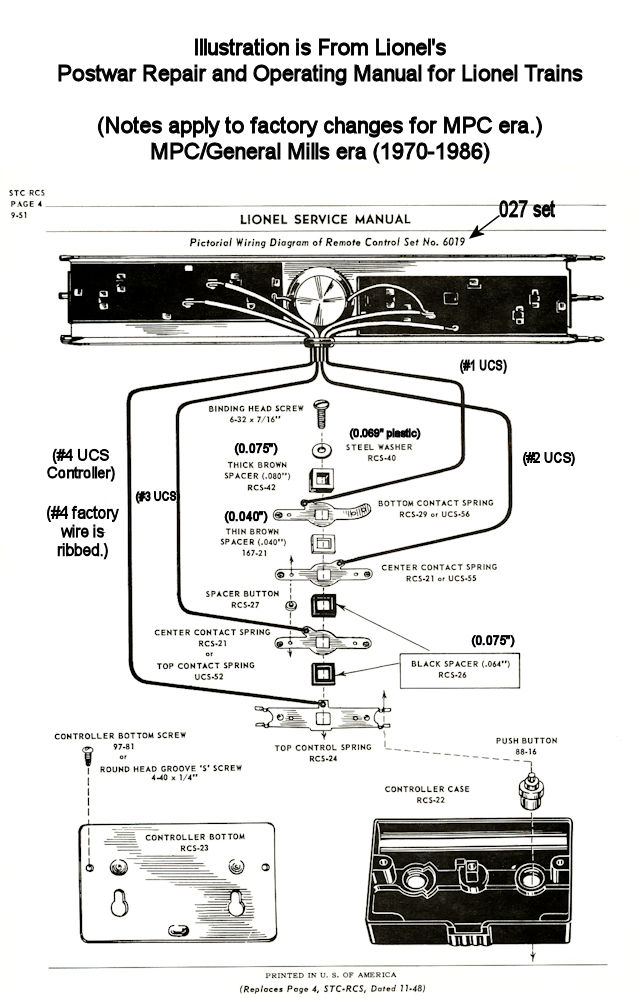

The track illustrated is Lionel's postwar 027 operating

track.

See pdf diagram here

for printing.

Before screwing assembly back into case, hold it together and

compare to Normal Position in above stack.

|

|

After

attaching stack to case, check contact spacing with a strip of index

card. The ST-302 spring adjusting tool is available as a reproduction from toy train parts dealers. The tool is also used to adjust switch (turnouts) spring contacts. |

MPC Era Controller Improvement

MPC/General Mills era (1970-1986) Lionel Corporation

The MPC redesign resulted in the square shaft breaking off with

user's rough treatment. My experience gluing structural

plastic parts has had poor results. This fix results in a

better Controller.

Both Controllers below were improved. The Controller on the

right had the broken square shaft. The shaft parts were glued

together and glue set before improvement.

For Improved Operation

Remove Spring assembly. Repair square shaft in cover

if needed.

Drill 7/64" pilot hole in square shaft from inside of cover to locate outside

center.

Drill 1/8" hole for 4-40 screw from outside.

The spring stack diagram below shows the difference from the postwar

spacers.

UCS Controller Improvement Parts (bottom center below)

Black 3/4" 4-40 phillips round head machine screws

18-8 Stainless Steel Hex Nut Black-Oxide, 4-40 Thread

Size

Black Nylon Plastic Washer for Number 4 Screw Size, 0.115" ID, 0.25"

OD

Improved MPC Controllers with Phillips Head on Top and Black Washer and Nut Inside

Reference Documents

- Schematic Wiring Diagram of Remote Control Set Type UCS and RCS

- Pictorial Wiring Diagram o Remote Control Set No. 6019

- Tracks and Controller Illustrations from Lionel Service Manual

- Postwar Remote Control Instructions

- MPC "O" Gauge Remote Control Track Set Instructions

- 2003 O Gauge Remote-Control Track Instructions

Return to Operating Cars and Accessories