Upgrade UP #80 Coal Turbine - Harness

Adapt #80, #80B, and Haness for the Larger PS2 Harness and Connectors

A certified MTH technician probably has a better way. This one works.

Evaluate Trucks for Solution

The PS1 harness channel in front truck of 80B is too small for PS2

harness.

| Top of #80 Rear Truck with PS2 Harness | Top of #80B Front 2 Trucks |

|

|

|

Bottom of 80 and 80B Trucks

Use Strain Relief for #80 Plug and New Routing for #80B Harness

| Custom Strain Relief Clips | 80B Front Truck Drilled for PS2 Harness |

| These clips (3

extras) are 1/16" thick steel. The 2 holes for attaching the plug are drilled and tapped for 4/40 RHMS. The stand offs used between slips and plug are standard circuit board stand offs. The cable hole is 3/16". The slot appears to be about 5/32" |

|

| #80 Top Strain Relief Assembly | #80 Bottom Strain Relief Assembly |

|

|

|

| #80 Strain Relief Assembly with Heat Shrink | #80 Strain Relief Cable Secured with 2 Tie Wraps |

|

|

|

Harness Connected and Installed Ready for Splicing for Longer Wires

80B Unit Front Truck Bottom with Cable Run

|

80B Front Truck Completed Wires used for splicing are 24 gauge 4 pair CAT5 cable with 1 pair for each PS2 conductor. |

|

Alternate Adaptation for #80 Connector/Plug

AG, MTH Authorized Converter, shared this adaptation with me. This method involves drilling and tapping the cast truck body.

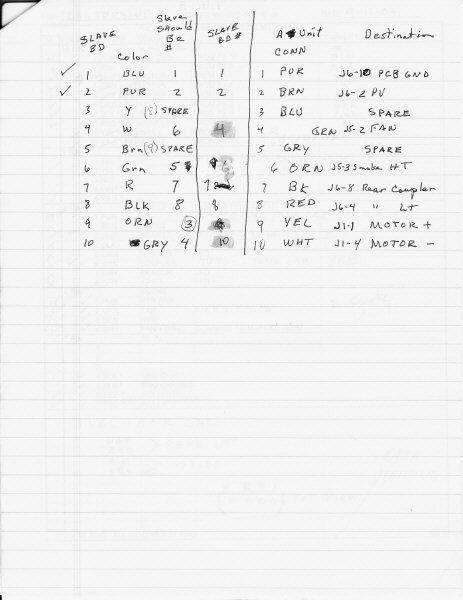

As Built Notes and Blank Checklists

AG, MTH Authorized Converter, shared this information that's very helpful.

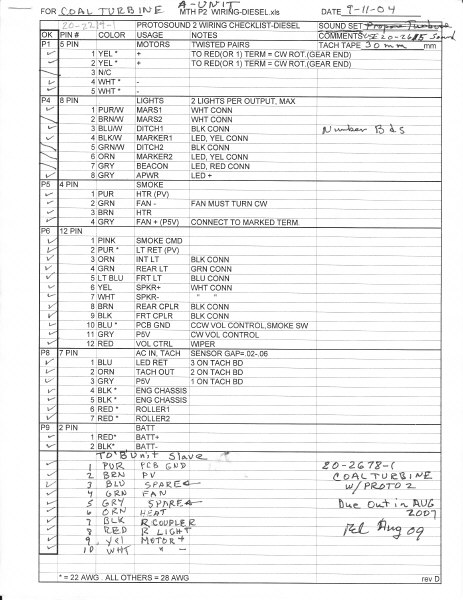

PDF file PROTOSOUND 2 WIRING CHECKLIST-DIESEL

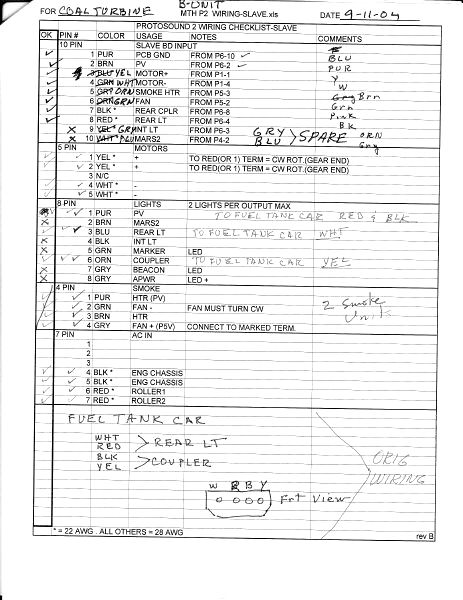

PDF file PROTOSOUND 2 WIRING CHECKLIST-SLAVE

Return to Upgrade UP #80 Coal Turbine