MTH 20-3383-1 2-3-1 Pacific Steam Engine

Engineering Edition with Proto-Sound 2.0 and Hi-Rail Wheels

MTH engines that are "Proto-Scale 3-2T 3-Rail/2-Rail Conversion Capable"

are now on my "No Buy" list.

This engine is "Proto-Scale 3-2T 3-Rail/2-Rail Conversion Capable"

and would not run through my #6 and #8 Ross Turnouts. The only

engine wheels that have any electrical contact with the outside

rails are the front and rear drivers and a wheel on the single axle

trailing truck. The front driver's rubber tires prevent track

contact. To get through the #8 turnouts the engine had to run

through at a scale 35 mph.

This engine is a really good runner and looks good naked so I want to keep it.

Improvements Enhanced 3-rail Operation.

The coating was cleaned off the contact wheels and trailing truck axle with no improvement.

The broken wipers were repaired with very little improvement.

| On the engine the rear single axle came with very fragile wipers that were damaged in handling. A replacement wiper was not readily available so I soldered a brass scrap for temporary use to the attached section of the original wiper. |

|

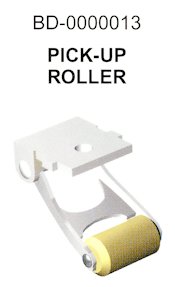

Adding a pick-up roller to the tender improved performance some.

Pick-up Roller Added to Tender

The engine's pickup rollers were too close to run through my

turnouts. The added pick-up roller did improve the engine

performance through the turnouts. The engine still had to

speed through the #8 turnouts.

|

|

The MTH 30-1590-1 4-6-0 Ten Wheeler caboose tender at left seems to have the same truck casting for a pick-up roller as my Pacific tender truck shown in bottom two photos. |

|

|

|

Digging through my parts unearthed these parts.

|

Parts used clockwise: insulator, pick-up roller, 4/40 rhms, 2 nuts, lock washer, contact strap, and red plastic insulated spacer tube. |

Part #s may be obsolete. |

|

|

The brown prototyping board above the red insulator is used as an insulator for the contact strap secured with the lock washer and 4/40 nut. |

|

The insulator and pick-up roller are

connected with the 4/40 rhms and nut then fitted to truck bottom.

From the top of truck insert the spacer between the pick-up

insulator and the brown insulator on top. The contact strap,

lock washer, and nut secure the brown insulating plate and the roller

assembly.

Secure the strap that was connected to the truck body screw.

Inside the tender attach the roller contact strap wire to the same

roller contact wire that comes to the tender from the engine. On my harness

it is the brown wire next to the white wire.

The engine still had to run through the #8 turnouts faster than I

liked.

The last attempt to improve performance involved compromising the 2-Rail capability.

The engine's 3 left side power pick-up

wheels are electrically common with the frame (not the axle). One

driver pick-up wheel has a rubber tire.

The engine's 3 right side power pick-up wheels are electrically

wired with special contacts. One driver pick-up wheel has a rubber

tire. These three wires are factory wired with a wirenut

through the harness to the 2-rail 3-rail tender slide switch.

The final effort to improve contact with the outside rails through

the #8 turnouts involved grounding the right side power wheels to

the frame in common with the left side wheels. The tender now has a

warning that the 2-rail wiring is shorted.

The engine can now run through at a scale 20 mph and is on probation. If it gets stuck on turnouts too often to keep me happy, out it goes.